FAG – Friedrich Fischer and Georg Schäfer

Kugelfischer mechanical fuel injection is rooted in Germany’s precision-engineering heartland. Its origins trace back to FAG Kugelfischer Georg Schäfer AG, founded on the work of Friedrich Fischer, whose late-19th-century development of precision ball bearings transformed mechanical engineering. Known locally as “Ball Fischer”—Kugel meaning ball—his name later formed the basis of Kugelfischer.

Following Friedrich Fischer’s death in 1899, the business entered a period of uncertainty. Through existing family and commercial ties, Georg Schäfer—already a minority shareholder—was able to acquire control of FAG in 1909. Under Schäfer’s leadership, the company expanded rapidly, with Kugelfischer evolving from a simple telegram address into a recognised industrial and engineering identity.

Based in Schweinfurt, the company’s strategic importance made it a primary Allied bombing target during the Second World War.

Schäfer Einspritztechnik

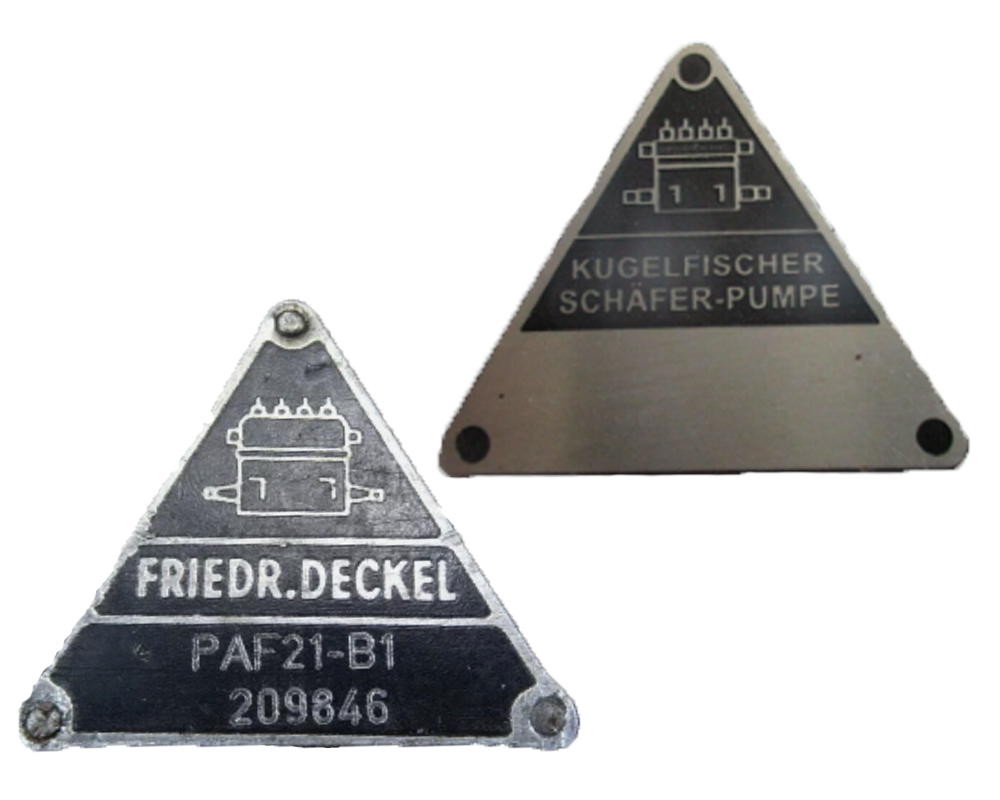

In parallel, Munich-based Friedrich Deckel GmbH was developing mechanically elegant fuel-metering systems derived from aviation requirements.

It appears that Deckel collaborated with Schäfer in the field of fuel injection, leading to the formation of Schäfer Einspritztechnik—effectively a special-purpose entity that would go on to absorb the injection business.

Evidence of this transition survives in period pump branding from the 1960s and early 1970s, variously marked “FRIEDR. DECKEL”, “SCHÄFER-PUMPE”, and “KUGELFISCHER SCHÄFER-PUMPE”.

Engineering Evolution: Munich, BMW, and Motorsport

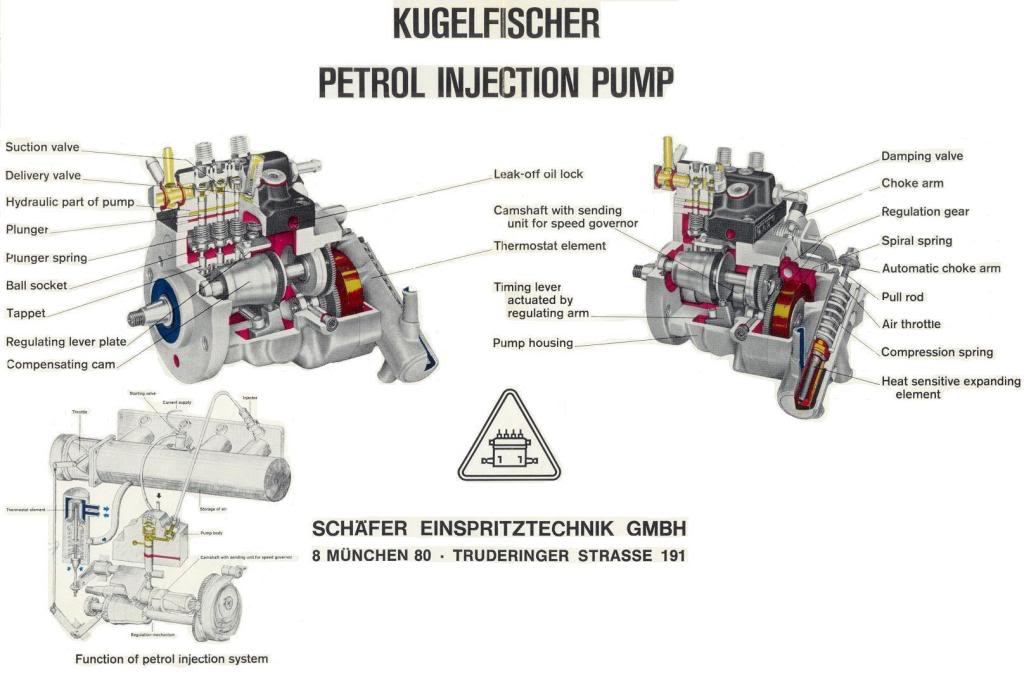

Fuel injection pump production later centred in Munich, where the Kugelfischer system evolved from the same aircraft-grade engineering culture that shaped early BMW engines. By the 1950s, Kugelfischer had perfected a mechanically driven, high-pressure injection system using a three-dimensional cam to meter fuel with exceptional accuracy and repeatability.

Between 1969 and 1975, BMW produced over 64,000 road cars equipped with Kugelfischer injection, including the 2002 tii and 2002 Turbo. With clean fuel and correct lubrication, these pumps routinely delivered 100,000–150,000 miles of reliable service—often more.

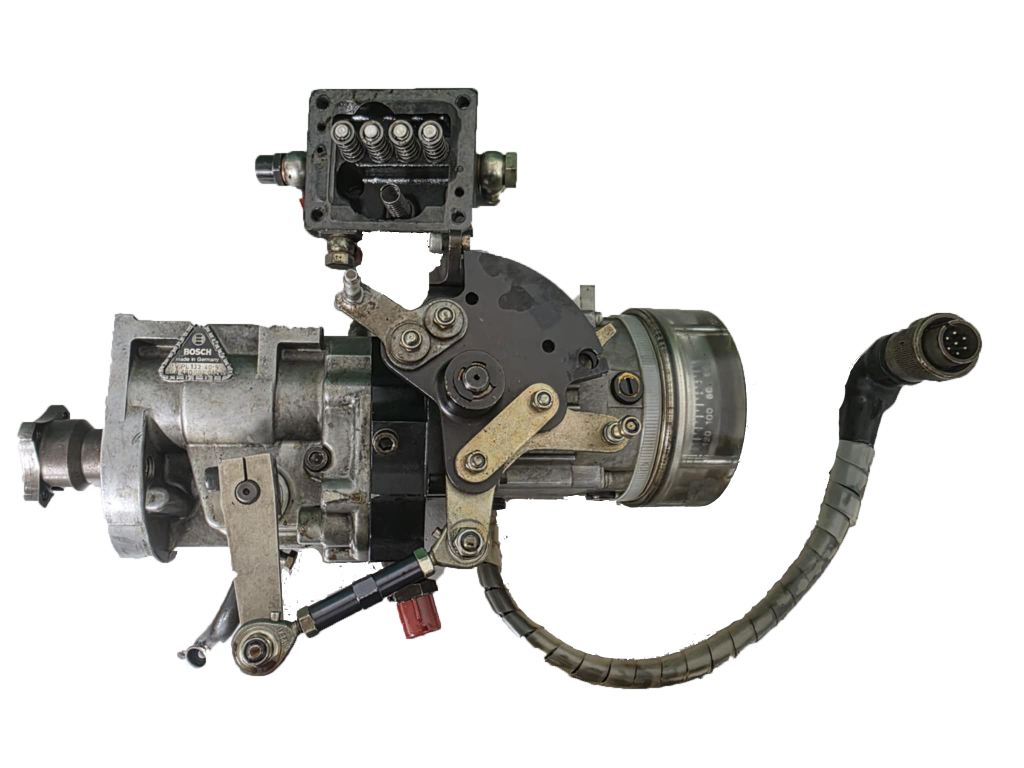

In 1975, the injection business was acquired by Robert Bosch GmbH. While Bosch shifted development toward electronic systems to meet emissions and flexibility requirements, Kugelfischer’s mechanical integrity ensured its continued use in high-performance and motorsport applications.

That reliability reached its peak in Formula One. BMW’s turbocharged BMW M12/13, producing over 1,350 horsepower, ran a servo-controlled Kugelfischer system in early 1980s competition—combining electronic control with purely mechanical fuel delivery, based on principles laid down by Friedrich Deckel decades earlier.

Precision Engineering, Applied Today

At Point85, we work within this lineage of precision as engineers, not curators. Kugelfischer is not obsolete technology; it is a fully understood mechanical system that delivers exceptional accuracy and reliability when built and calibrated correctly.

Deep technical knowledge underpins every pump we work on, from component manufacture and calibration through to operation at the limit. Each Kugelfischer system leaves our workshop rebuilt, remanufactured, and calibrated as a functional, performance-critical component—engineered to operate exactly as intended.

Using high-quality replacement parts, precise modern calibration equipment, and a detailed understanding of the demands of both circuit racing and the harsh environments of rallying, we tailor every rebuild to maximise power delivery, throttle response, and long-term durability.

For classic BMWs, Ford, and other vehicles equipped with Kugelfischer systems, Point85 delivers the expertise and attention to detail that drivers and teams rely on to achieve consistent, competitive results